Manufacture Your Product

Embark on your journey to bring your product to life, as we ensure that you have everything covered to launch your product successfully, from production setup to market introduction.

We’ll help you build a comprehensive plan and toolkit to successfully manufacture and launch your product, paving the way for a successful market entry and long-term growth.

Prototypes, Testing & One-Offs

Our facilities are perfect for producing prototypes and one-off product samples to serve as tangible proofs of concept. Whether you need to validate an idea or create a limited-edition masterpiece, our expertise ensures precision and creativity in every detail.

-

Rapidly test variations of the design in cardboard or perspex with our in-house laser-cutting and bending services.

-

Test the functionality of your product with a fully functional physical prototype, minus the cost and delay of hi-fidelity samples.

-

Test the final aesthetics of the product in materials that closely match production characteristics and materials.

-

Need only a hand-full of high quality product samples? Our facilities can bypass the limitations of minimum order quantity requirements of mass production facilities.

-

Depending on design requirements, some products may need unique testing procedures. We can flexibly facilitate testing and demonstration of prototypes, including proof of concept demonstrations, functional, environmental, reliability, usability, safety and destructive tests.

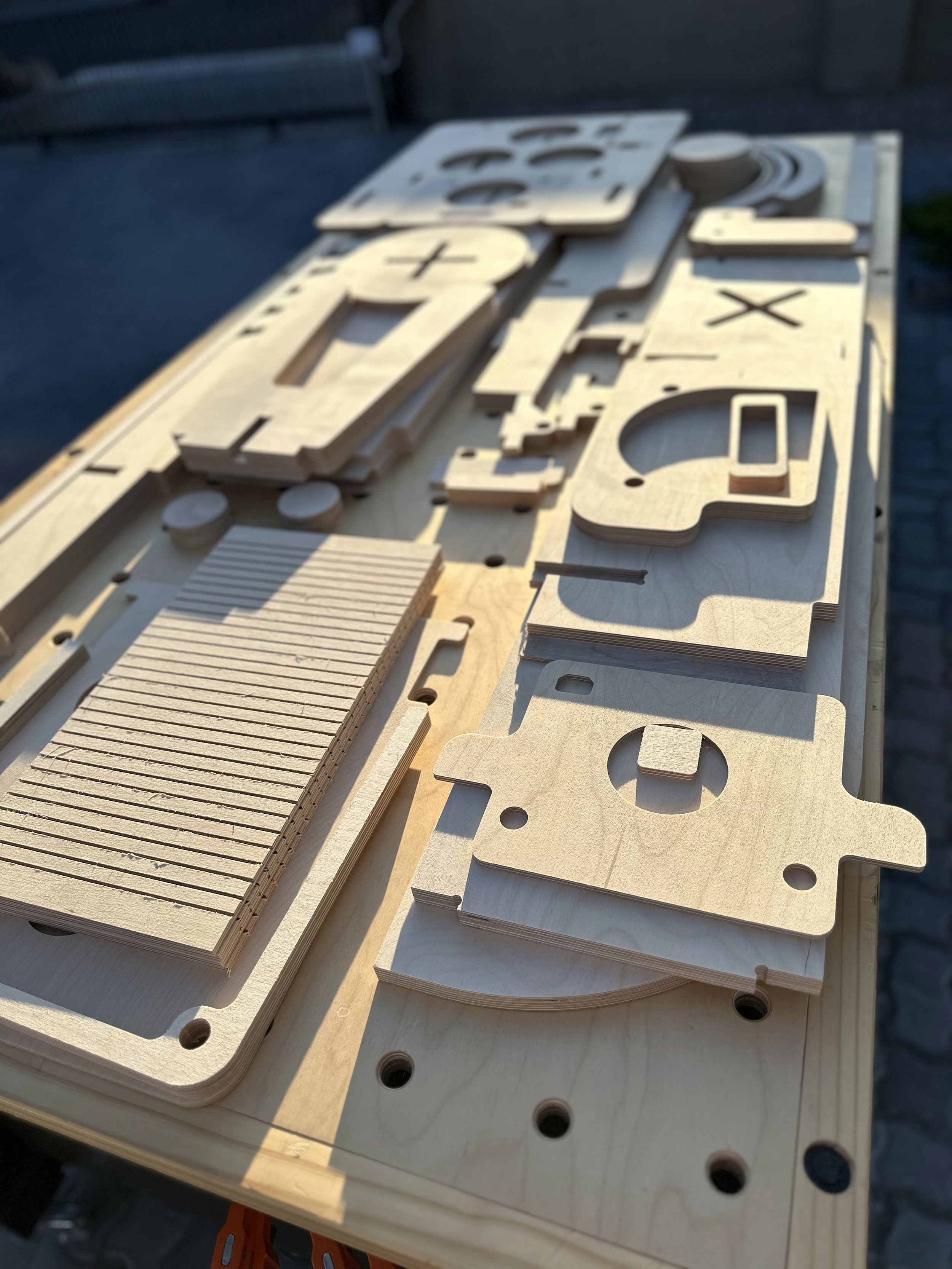

Small-Batch Production & Assembly

Our state-of-the-art facilities enable us to oversee small batch production and assembly under our own roof, ensuring increased attention to detail, quality control and efficient assembly.

-

Our in-house fabrication facilities include plastics- and paper-based laser-cutting, plastics line-bending, CNC machining, welding among various other hand and machine operated processes.

-

Our trusted supplier network ensures high-quality production using a multitude of processes.

These include sheet-metal fabrication, welding, laser-cutting, CNC-machining in various materials, local injection-moulding and thermo-forming, hi-res 3D printing in various materials, woodwork, engineering materials, finishing and coating.

Our network also enables us to source any additional manufacturers for products with unique requirements.

-

-

Every project is unique and requires a tailored approach. We will run you through all the options and cater for your specific project requirements.

Could we be the right fit for your business?

Other Packages